_ PHARMA SECTOR

Founded in 1941, CKD is a leading biotech and pharmaceutical company in Korea and a leading Korean pharmaceutical manufacturer. It became the first Korean pharmaceutical company to export products to the US market through obtaining US FDA approval.

Over the past decade, Chong KunDang has partnered with multinationals such as Bayer, Roche, Allergan Pfizer and MSD and Amgen and, as a result, Chong Kun Dang has unrivaled leadership in the local market, reinforced by its strong product portfolio which it now covers a wide range of therapeutic classes with innovative and exceptional drugs.

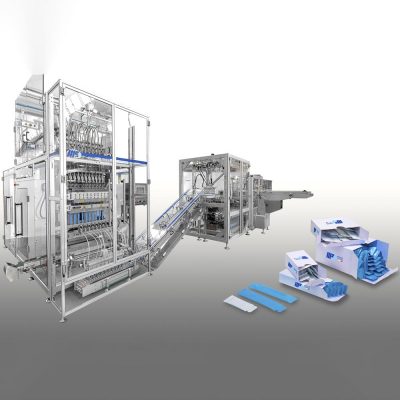

Their high-tech manufacturing facility, the Cheon-An factory located in Cheon-An City, Chung Cheong Nam Do, has an area of 68,901m² and a gross floor area of 146,296m². production, packaging and release of finished products is controlled by an automated storage system.

Needs and objectives

CKD’s need was to adopt a complete and integrated packaging solution, able to offer maximum production capacity and maximum flexibility in the number of sticks for each carton. All in compliance with the needs of the pharmaceutical market and in compliance with the regulations of the pharma industry.