4SB for granular products

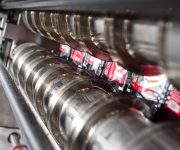

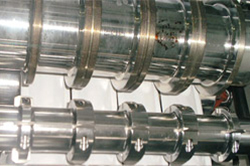

The Vertical 4-seal Multi-line Packaging Machine for granular products features a batching system with oscillating cups for sliding products.

Available in versions from 2 to 20 lines, it can reach a maximum speed of 250 cycles per minute, depending on the sachet format, product features and kind of packaging material.

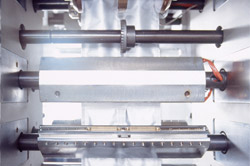

The 4SB Packaging Machine is reliable, simple to use and does not require excessive maintenance or qualified personnel.

Option of installing the remote support system to control the management software.

Its nice compact design makes it very easy to clean.

Features

Gallery

Video

Technical Details

Accessories

Technical features:

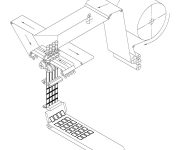

Number of lines: from 2 to 20

Max reel diameter: 700 mm

Max reel length: 1200 mm

Bag length: variable from 30mm to 250mm

Bag width: fixed or variable depending on the number of lines

Production speed: up to 250 cycles/min

Max volume that can be packaged: 300 cm3

Drive unit: Brushless motors

Single-colour flexo printing unit: It is installed in line with the packaging machine to print the wrapping film using one colour. It is particularly used in sectors requiring packaging with custom graphics. Extremely versatile, the various cliché rollers are very easy to change and are available in various diameters depending on the bag format or kind of graphics. Entirely electronic, it lets you change phase synchronisms whenever you want, even during the printing stage. Fitted with a self-washing system, it does not require too much time to clean it.

Thermal transfer rotary marker: It is installed in line with the packaging machine to print the batch details and use-by date with thermoplastic ink. Extremely versatile, you can easily put together words and/or numbers by adding or removing characters on four lines. It is produced in versions with 1 head or several heads according to the number of lines on the packaging machine. Entirely electronic, it lets you change phase synchronisms whenever you want.

Dry rotary marker: Used to dry imprint the batch details and use-by date on the packaging’s sealing area. Extremely versatile, you can easily put together words and/or numbers by adding or removing characters.

Dry rotary marker: Used to dry imprint the batch details and use-by date on the packaging’s sealing area. Extremely versatile, you can easily put together words and/or numbers by adding or removing characters.

Semi-automatic carton filling unit to collect untidy bags: consisting of an 1800mm long belt, vibrator in the filling station, automatic carton ejection with the count is reached, manual feeding of empty boxes and photocell to report when there are no boxes.

Bag diverter flap: used to count and divert the flow of bags produced without a specific order from one container to the next.

Product Feeder: To automatically feed the product that needs to be packed whilst always keeping the level in the packaging machine’s hopper constant. Fitted with a system to automatically stop the machine when there are no more products.

Product Feeder (pneumatic): Via a pipe located in a container, the system draws in the product, which is automatically fed to the packaging machine’s hopper. The level in the packaging machine is always constant and there is a system to automatically stop the machine when there are no more products..

Ponderal sorter: To check weight with a system to eject packages exceeding tolerance limits and automatic batching correction (feed-back system).

Euro lock rotary die-cut: To make the euro lock hole in the packaging’s sealing area.

Technical details

Fill out the form to receive more detailed information.